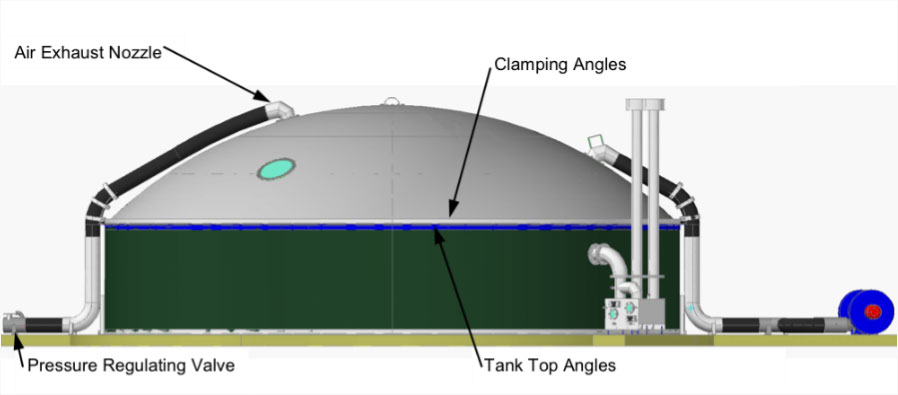

JOG-CSTR Technology

We offer the design and construction of completely wet mixed Digesters. These Digesters work at a low total solids-content and can be used as main Digesters, or as post-Digesters.

JOG uses this type of technology for All type of Biodegradable Waste and clean and wet organic feedstock such as energy crops, agro-industrial residues or food waste. The JOG-CSTR is a continuously stirred Digester with Biogas storage on Top.

JOG-CSTR Characteristics

- Round Digester in concrete construction

- Total solids content between 2 and 15% in the Digester

- Mesophilic or thermophilic operating Temperature

- Easy replaceable stirrers

- Modular concept

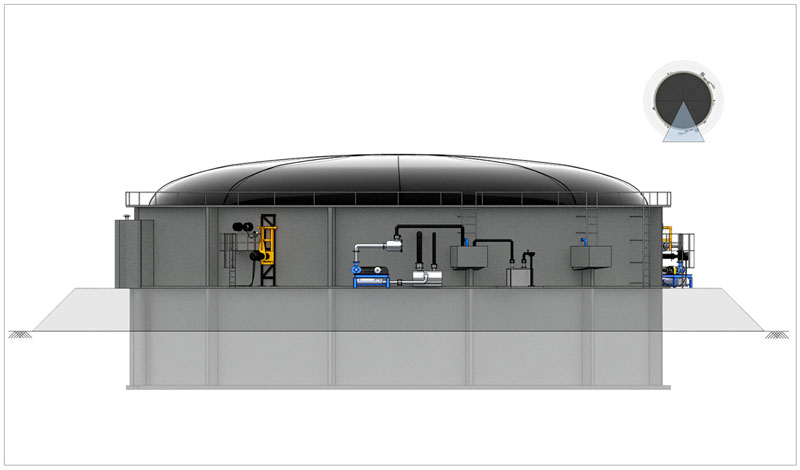

Full Digester Package Includes

- Concrete Foundation

- Digester tank wall

- UPVC BioGas Holder/Balloon

- Insulation

- Inclined side Entry type agitator

- Ladders & work platform

- Manhole

- Water level measurement

- Inspection windows (illuminated)

- Overpressure safety valve

- Gas Pipe

- Tank wall ducts & flanges

- Design for mesophilic operation

- Including construction & commissioning

Optional Equipment

- Design for thermophilic operation

- Sludge discharge pipe to the Digester center for complete draining and sludge removal

- Self-cleaning inspection windows

- External Digester Heating With Heat Exchangers

- Floating layer Outlet

- Foam Sensor and Spraying Nozzles

- Measurement devices for temperature, pH, gas pressure, gas quality

- Overflow protection

- Manhole with inspection window

JOG-CSTR Advantages

The JOG-CSTR process has some significant advantages:

- Simple Design

- Short Construction period

- Optimal heat- and material distribution inside the Digester

- Limited Height

- Efficient degassing inside the Digester

- Large Digester volumes possible